Breakthrough in Thermoelectric Materials: Hybrid Design Doubles Efficiency

Researchers from several prestigious institutions, including Los Alamos National Laboratory and TU Wien (Vienna University of Technology), have developed a groundbreaking type of hybrid thermoelectric material that enables more efficient conversion of heat into electricity. This discovery marks a major step forward in sustainable energy use and opens up new possibilities for wearable devices, autonomous sensors, and even next-generation power generators.

What Are Thermoelectric Materials?

Thermoelectric materials can directly convert temperature differences into electric current—a phenomenon known as the Seebeck effect. These materials are used, for instance, to capture waste heat from exhaust systems, in thermoelectric coolers, or in autonomous power supplies. The biggest challenge in their development has always been to find a material with high electrical conductivity but very low thermal conductivity—two properties that often conflict with each other.

The Innovative Solution: A Hybrid Material

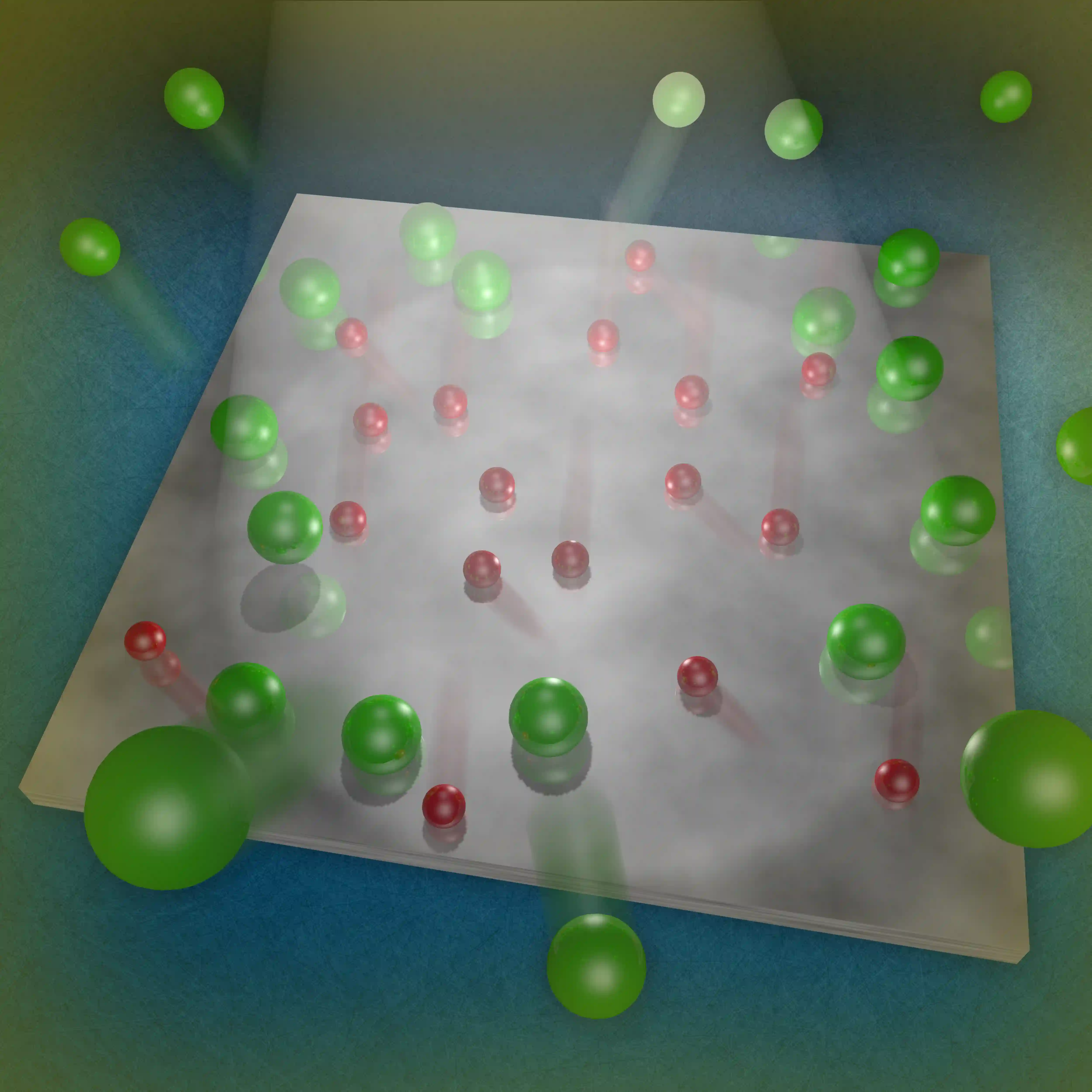

The researchers new approach combines two different materials with similar electronic properties but very different thermal behaviors. They merged a Heusler-based alloy (Fe₂V₀.₉₅Ta₀.₁Al₀.₉₅) with a bismuth-antimony mixture (Bi₀.₉Sb₀.₁).

These components were joined using a technique called liquid-phase sintering—a process in which highly specific grain boundaries are formed during melting. These boundaries act as barriers to thermal vibrations (phonons), significantly reducing the overall thermal conductivity of the material.

At the same time, the electrical conductivity is not compromised—in fact, the grain boundaries may serve as topologically protected channels that improve charge transport. This effect has been intensively studied in recent years, particularly in relation to topological insulators.

Results and Performance

The outcome of this approach is a hybrid material with unprecedented performance parameters. The figure of merit (zT)—a key indicator of thermoelectric efficiency—reaches values around 0.5 at room temperature, which is remarkable for this category.

Lower thermal conductivity and improved stability also make this material much more reliable for long-term use. According to the researchers, compared to traditionally used materials like bismuth telluride, the new hybrid offers lower cost and higher mechanical and chemical stability.

Potential Applications and Future Outlook

Thermoelectric generators could soon become a standard component in smart devices—like sensors powered by body heat, battery-free medical wearables, or even clothing that generates its own energy. New materials that convert heat into electricity more efficiently could also revolutionize the automotive industry by harvesting waste heat from engines during operation.

According to the authors of the study, this is only the beginning. Hybrid materials represent a new design framework that could also be applied to other areas, including batteries and low-power electronics.